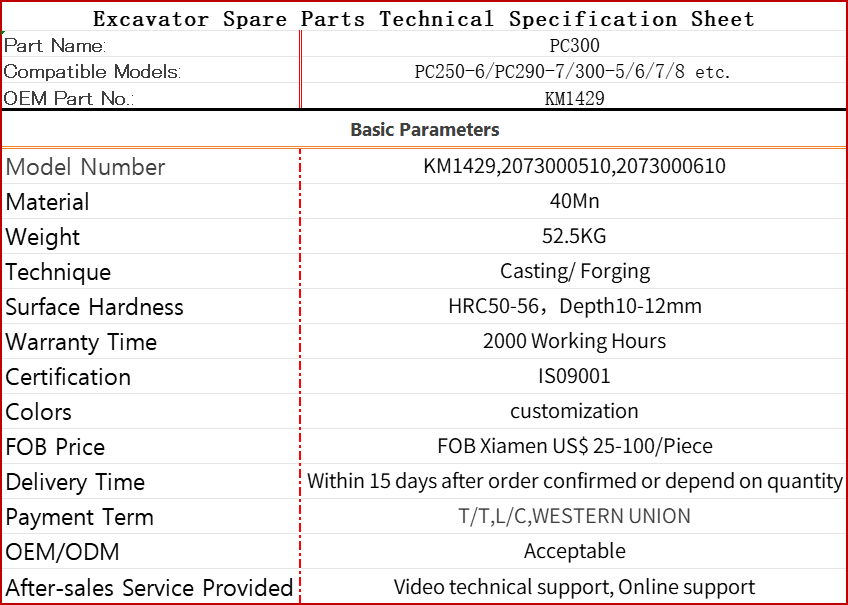

Komatsu excavator PC300(KM1429,2073000150,2073000511)track roller/komatsu track rollers parts/flanged track rollers/DPW-parts

Product Specifications

Komatsu excavator PC300(KM1429,2073000150,2073000511)track roller/komatsu track rollers parts/flanged track rollers

Here's a detailed technical breakdown of Komatsu PC300 Bottom Rollers, covering all generations (PC300-5 through PC300-11):

Komatsu PC300 Bottom Roller Specifications

(Verify with your serial number at Komatsu Parts)

1. Model Compatibility

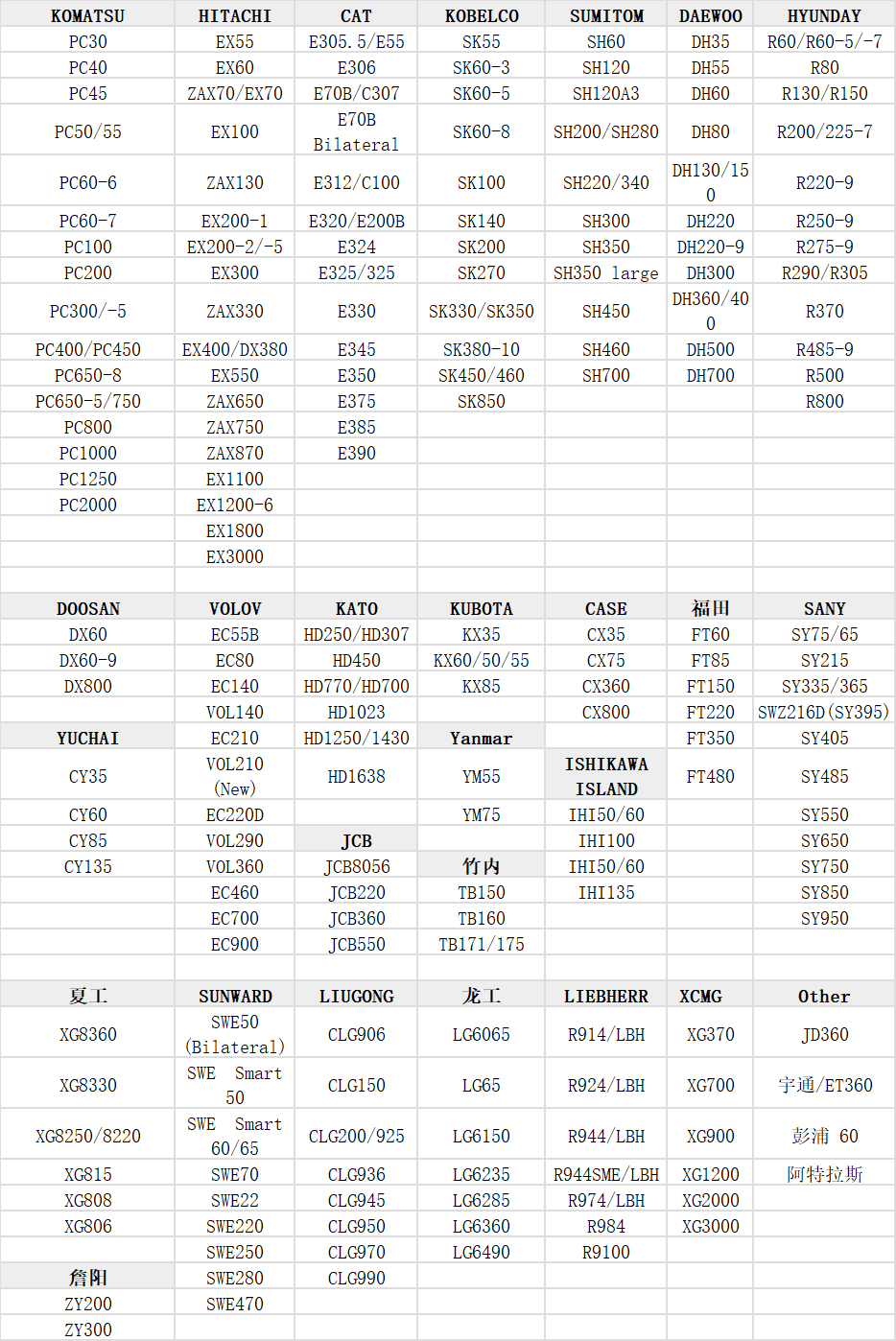

PC300 Generation OEM Part Number Rollers per Side PC300-5/PC300LC-5 20Y-70-21110 7 PC300-6/PC300LC-6 20Y-70-21120 7 PC300-7/PC300LC-7 20Y-70-21130 8 (LC models) PC300-8/PC300LC-8 20Y-70-21140 8 PC300-10/PC300LC-10 20Y-70-21150 9 (LC models)

| PC300 Generation | OEM Part Number | Rollers per Side |

|---|---|---|

| PC300-5/PC300LC-5 | 20Y-70-21110 | 7 |

| PC300-6/PC300LC-6 | 20Y-70-21120 | 7 |

| PC300-7/PC300LC-7 | 20Y-70-21130 | 8 (LC models) |

| PC300-8/PC300LC-8 | 20Y-70-21140 | 8 |

| PC300-10/PC300LC-10 | 20Y-70-21150 | 9 (LC models) |

2. Technical Specifications

Parameter OEM Standard Aftermarket Equivalent Material SCr440 Forged Steel 42CrMo Alloy Steel Weight 34-38 kg 32-40 kg Outer Diameter 180±0.5 mm 178-182 mm Width 68±0.3 mm 66-70 mm Bearing Type Tapered Roller Double-Sealed Ball Load Capacity 9,000 kg (static) 8,500-10,000 kg

| Parameter | OEM Standard | Aftermarket Equivalent |

|---|---|---|

| Material | SCr440 Forged Steel | 42CrMo Alloy Steel |

| Weight | 34-38 kg | 32-40 kg |

| Outer Diameter | 180±0.5 mm | 178-182 mm |

| Width | 68±0.3 mm | 66-70 mm |

| Bearing Type | Tapered Roller | Double-Sealed Ball |

| Load Capacity | 9,000 kg (static) | 8,500-10,000 kg |

3. Wear Limits & Maintenance

Flange Thickness:

New: 22-25 mm

Replace at: ≤12 mm

Bearing Play:

Allowable: ≤1.2 mm radial

Critical: >1.5 mm

Greasing:

Interval: Every 50 hrs

Grease Type: Komatsu GL-2 or equivalent

Volume: 120-150cc per roller

Flange Thickness:

New: 22-25 mm

Replace at: ≤12 mm

Bearing Play:

Allowable: ≤1.2 mm radial

Critical: >1.5 mm

Greasing:

Interval: Every 50 hrs

Grease Type: Komatsu GL-2 or equivalent

Volume: 120-150cc per roller

Visual Identification Guide

OEM Markings:

Laser-etched "KOMATSU" + part number

Blue paint stripe (genuine parts)

Aftermarket:

Berco: "BERCO" stamped + yellow zinc plating

ITR: "ITR" logo + red oxide primer

OEM Markings:

Laser-etched "KOMATSU" + part number

Blue paint stripe (genuine parts)

Aftermarket:

Berco: "BERCO" stamped + yellow zinc plating

ITR: "ITR" logo + red oxide primer

Replacement Procedure

Tools Required:

1" impact wrench (for M16 bolts)

10-ton jack stand

Track press (if removing chain)

Step-by-Step:

Release track tension (grease cylinder)

Remove track chain (if needed)

Unbolt old roller (180-200 Nm torque)

Clean mounting surface

Install new roller with anti-seize compound

Torque bolts in crisscross pattern

OEM vs Aftermarket Comparison

Factor OEM Premium Aftermarket Price $480-680 $350-550 Lead Time 2-4 weeks 1-2 weeks Warranty 12 months 6-12 months Bearing Life 8,000-10,000 hrs 6,000-9,000 hrs Seal Effectiveness 95%+ 85-90%

| Factor | OEM | Premium Aftermarket |

|---|---|---|

| Price | $480-680 | $350-550 |

| Lead Time | 2-4 weeks | 1-2 weeks |

| Warranty | 12 months | 6-12 months |

| Bearing Life | 8,000-10,000 hrs | 6,000-9,000 hrs |

| Seal Effectiveness | 95%+ | 85-90% |

Recommended Suppliers

OEM:

cqctrack&DPW-parts

Local Komatsu dealers

OEM:

cqctrack&DPW-parts

Local Komatsu dealers

Troubleshooting Guide

Symptom Root Cause Solution Uneven track wear Misaligned rollers Replace entire set Grinding noise Failed bearings Immediate replacement Grease leakage Seal damage Rebuild with new seals Roller not turning Corrosion/contamination Clean and regrease

| Symptom | Root Cause | Solution |

|---|---|---|

| Uneven track wear | Misaligned rollers | Replace entire set |

| Grinding noise | Failed bearings | Immediate replacement |

| Grease leakage | Seal damage | Rebuild with new seals |

| Roller not turning | Corrosion/contamination | Clean and regrease |

Pro Tips

Always replace rollers in matched sets (minimum both sides)

PC300LC models may require different spacing than standard

For mining applications, consider HD versions with thicker flanges

Keep 1-2 spare rollers for emergency replacements

Always replace rollers in matched sets (minimum both sides)

PC300LC models may require different spacing than standard

For mining applications, consider HD versions with thicker flanges

Keep 1-2 spare rollers for emergency replacements

Need Exact Part Verification?

Provide:

Machine serial number (located on right frame)

Current roller photos (showing wear patterns)

Application (e.g., mining, construction)

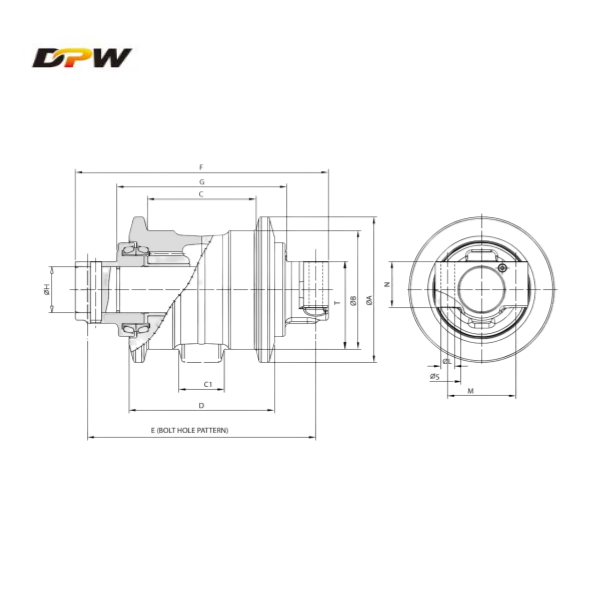

I can then provide generation-specific diagrams or local supplier contacts!